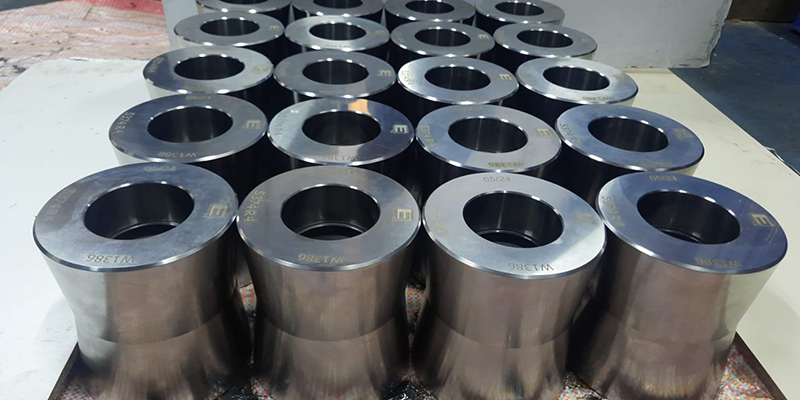

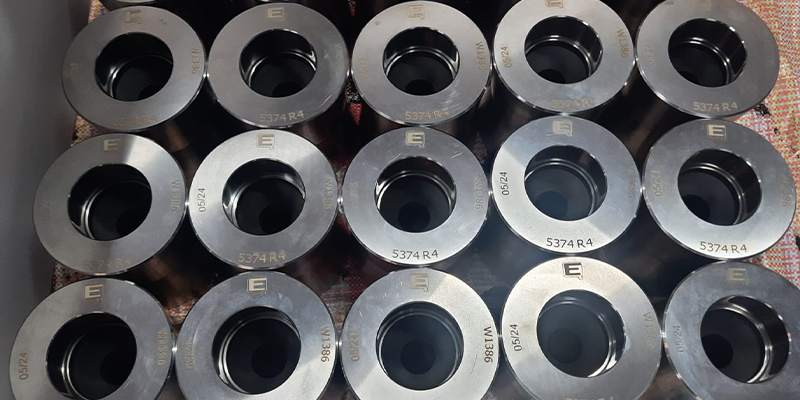

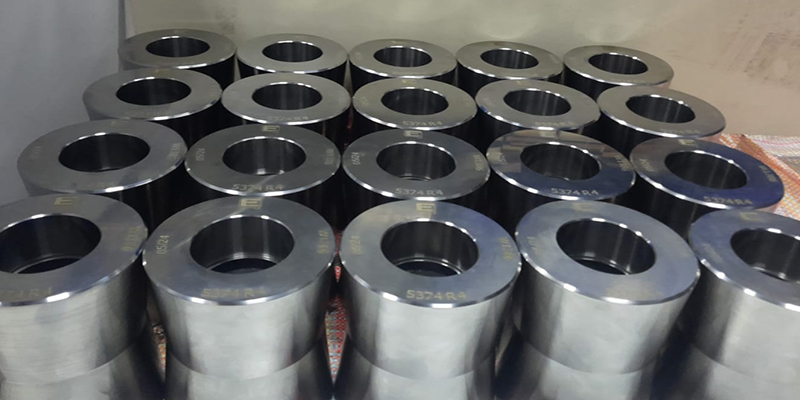

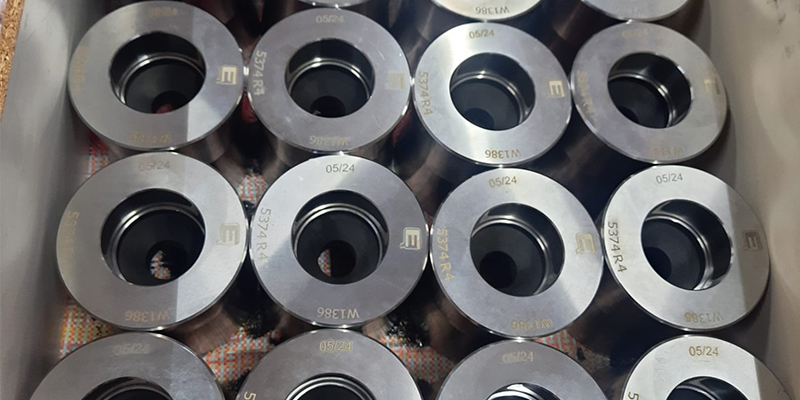

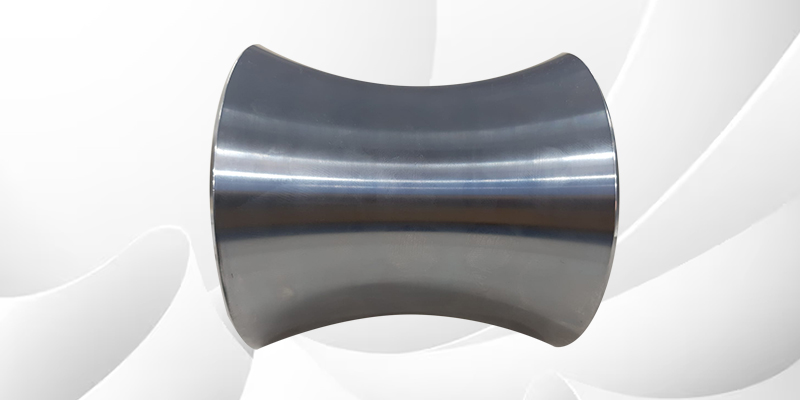

In rolling mills, entry and exit guide rollers play a crucial role in ensuring smooth rolling of the stock. Let’s dive into the details:

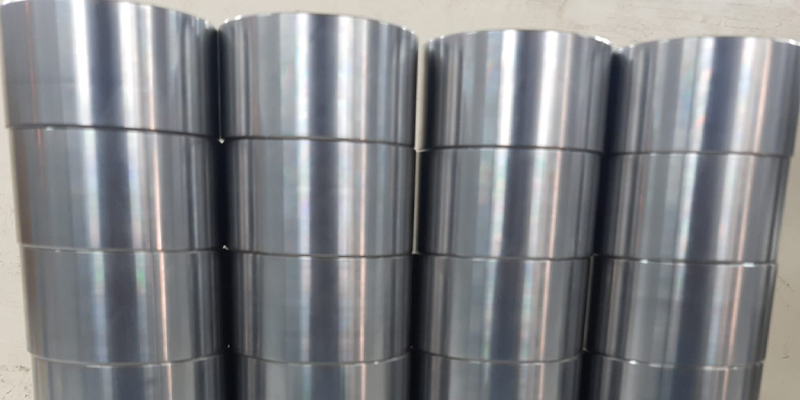

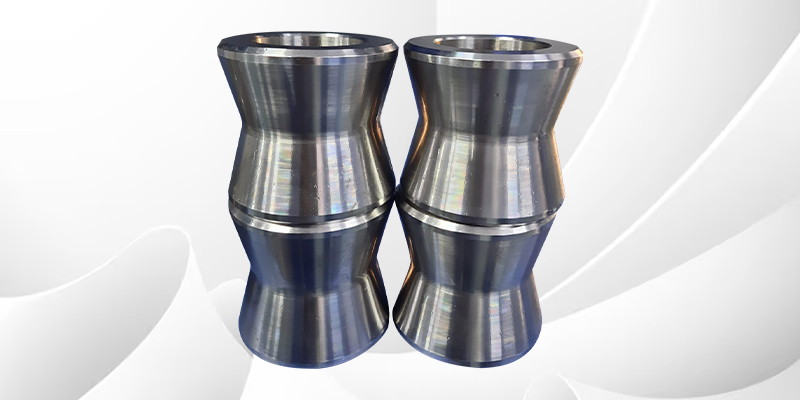

1. Entry Guide Rollers:

- Positioned at the entry side of the rolling mill.

-

Purpose:

- Guidance : Direct the stock into the roll pass.

- Alignment : Maintain proper alignment to reduce distortion during rolling.

-

Types :

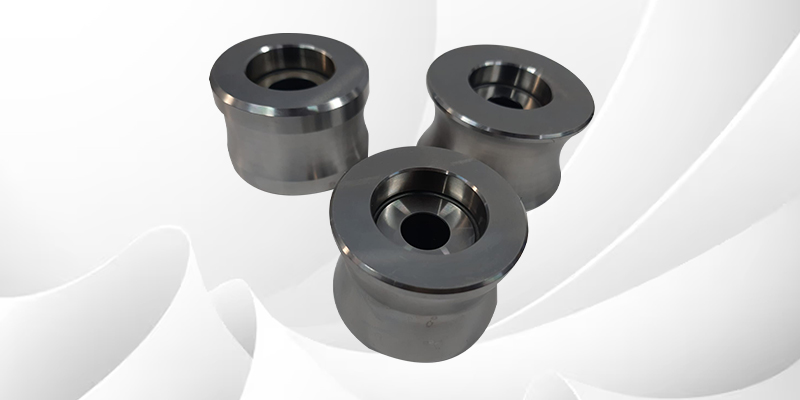

- Sliding or Static Guides:

- Based on sliding friction.

- Comprise a guide box, opposed blocks, and metal plates.

- Robust design to withstand the mill environment.

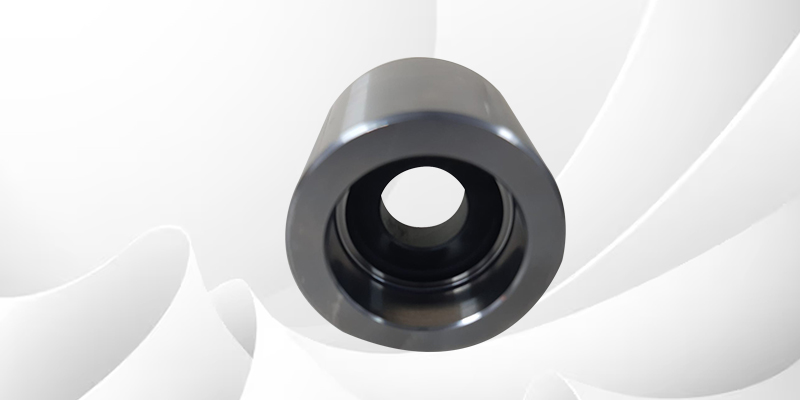

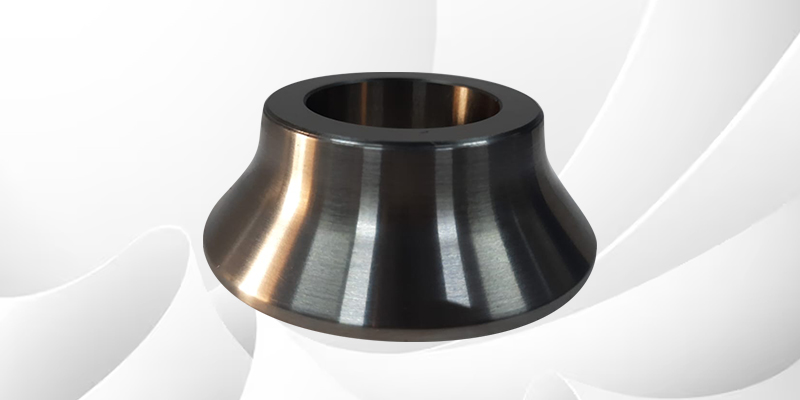

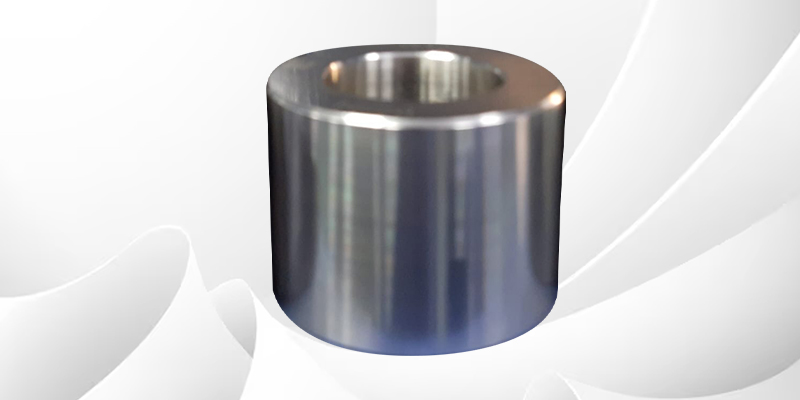

- Roughing Mill Entry Guides:

- Fabricated steel design with replaceable wear plates.

- Substantial wear allowance.

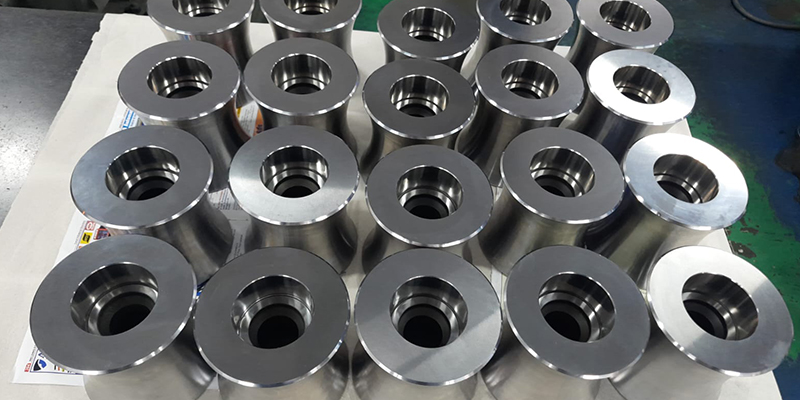

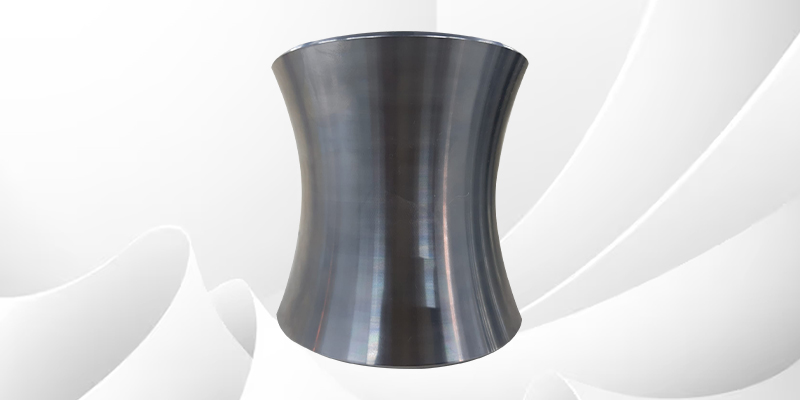

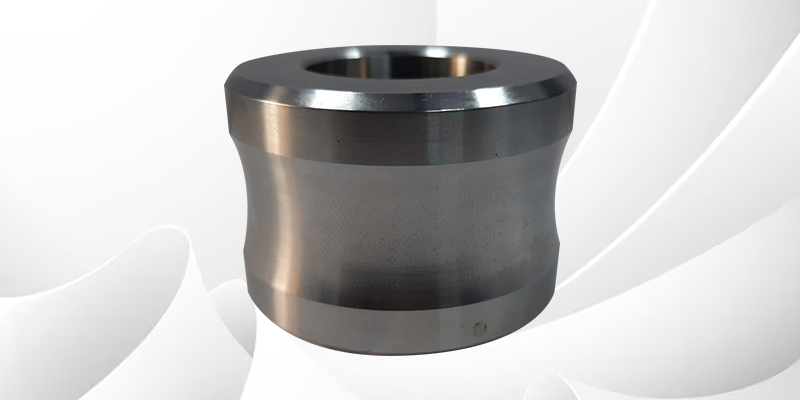

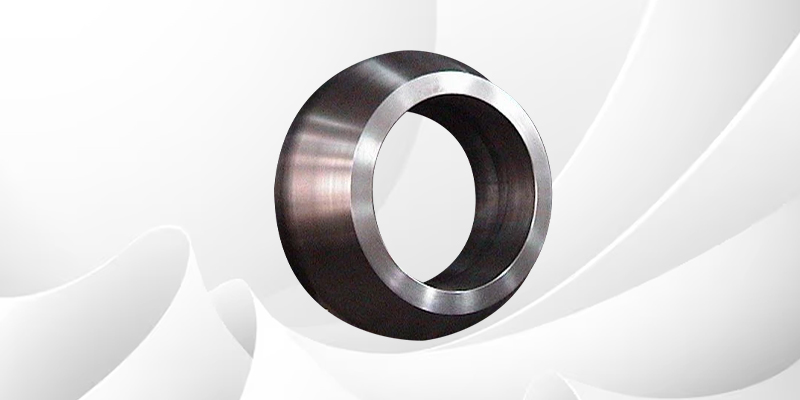

- Intermediate Mill Entry Guides:

- Interlocking cast steel halves for rigidity and easy interchangeability.

- Water-cooled design to remove scale buildup.

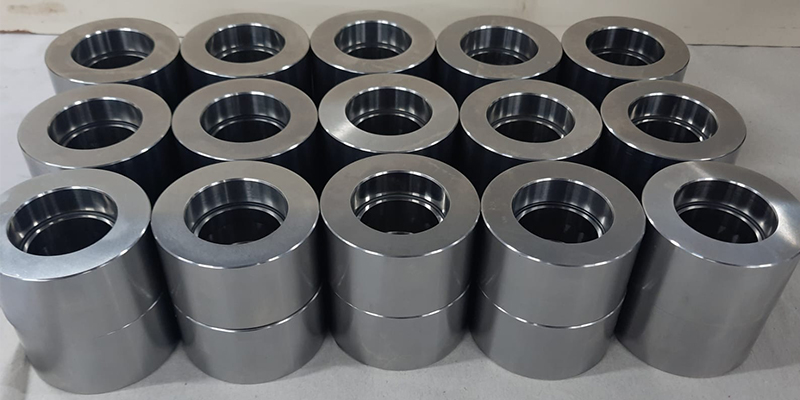

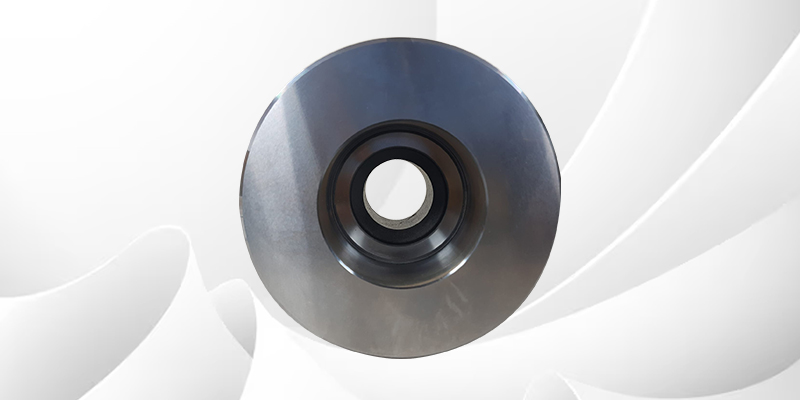

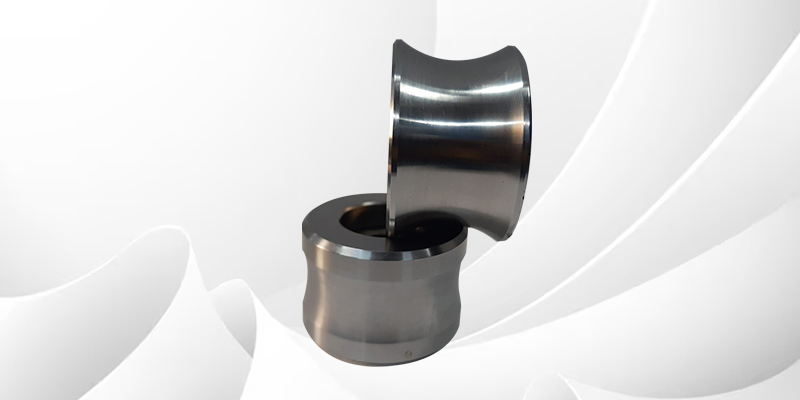

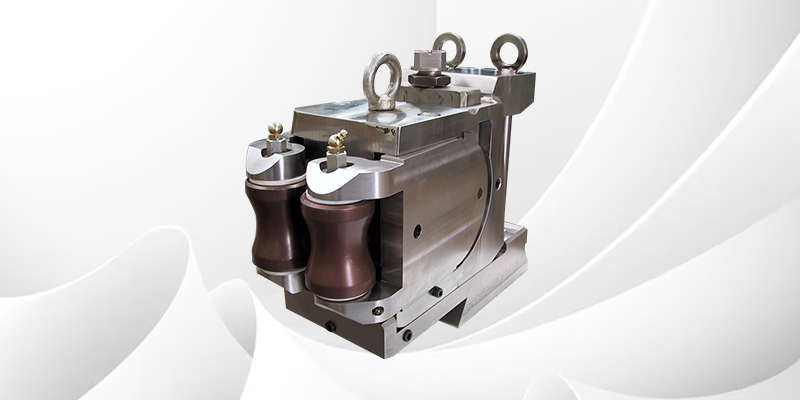

Exit Guide Rollers :

- Positioned at the exit side of the roughing mill.

-

Purpose:

- Ensure optimum stock delivery from the mill stand.

- Facilitate smooth transition through mill stands.

-

Design :

- Two cast steel inserts with integral locking arrangement.

- Easily mounted and secured for stability.

These guide rollers are essential for maintaining surface quality and stability during the rolling process. If you have more questions, feel free to ask