Twister guide rollers play a crucial role in rolling mills, especially for guiding and twisting the rolled stock.

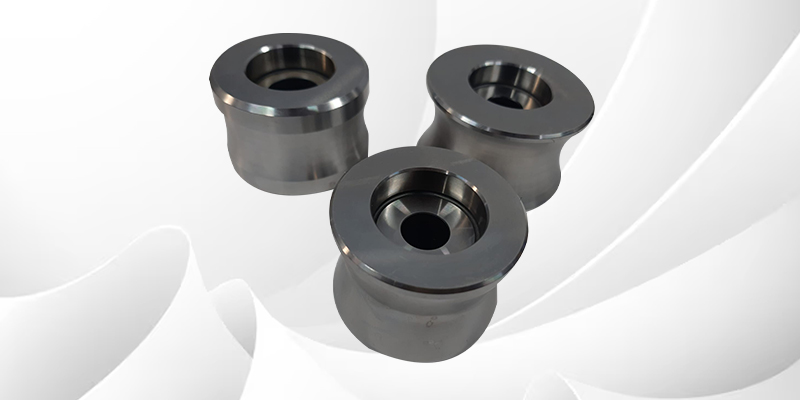

RTC-RS Twisting Guides

- These guides are well-proven for bar and wire rod mills.

- Features:

- Cantilever design: Allows the use of rollers with larger diameters and bigger bearings, resulting in longer utilization time and higher load capacity.

- Visually-controlled rollers: Immediate twisting control.

- Quick-replacement rollers: Easy maintenance.

- Central point adjustment: Maintains the perfect centerline through simultaneous and symmetrical roller adjustments.

- Long-life components: Durable design.

- Mounting options: Fixed base or cassette-type mounting available.

- Reduced twisting angle: Twisting point close to the stand minimizes load on bearings.

- Guide sizes: RTC-1RS, RTC-3RS, RTC-5RS, RTC-7RS, RTC-10RS, RTC-12RS, RTC-15RS, RTC-18RS1.

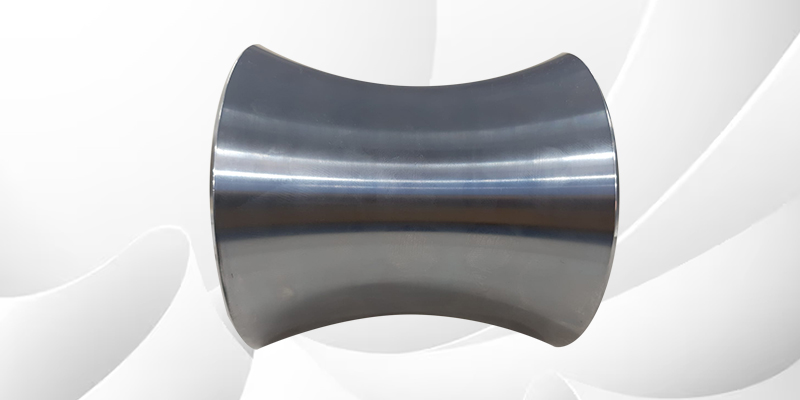

Roller Guide for Rolling Mill :

- A series of rollers that determine the angle and direction of the steel as it passes through the rolling mill to the mill roll.

- Ensures precise guidance and twisting of rolled stock.

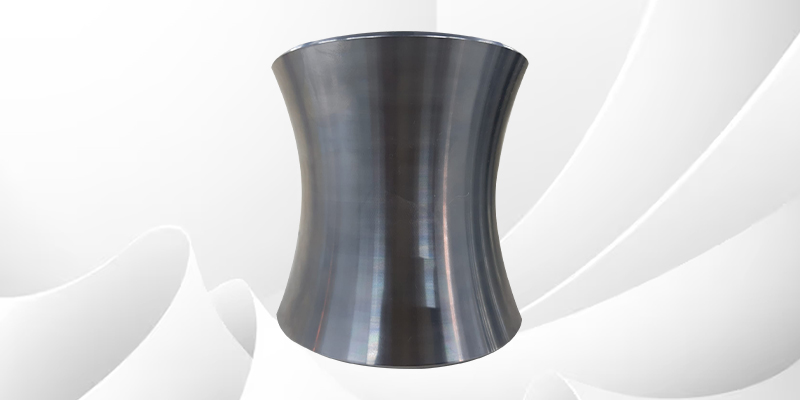

Exit Twist Guide :

- Designed for stability, especially with greater interstand distances.

- Accommodates plane or profile rolls.

- Features symmetrical roll gap adjustment and an easily accessible single-point twist angle mechanism.

These guides rollers are essential for maintaining precision and stability during the rolling process