In the context of rolling mills, let’s explore the concept of rollers and their significance:

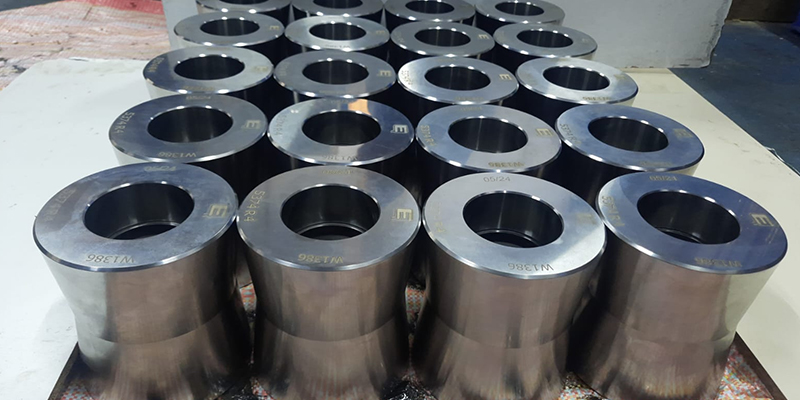

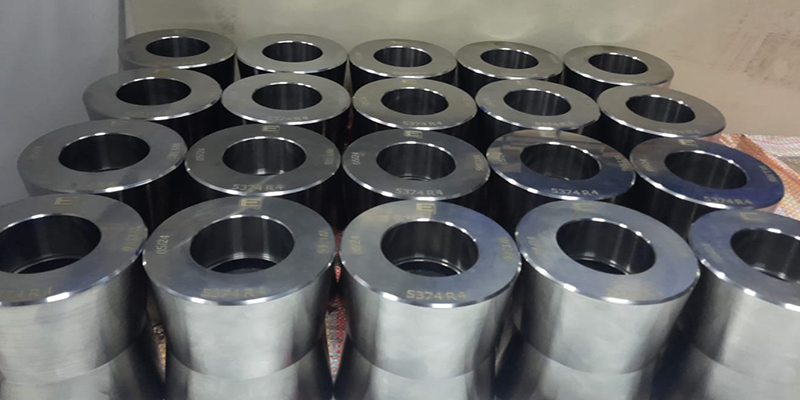

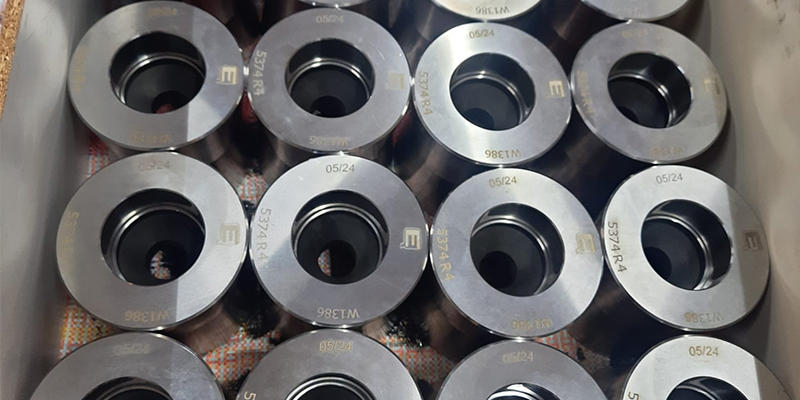

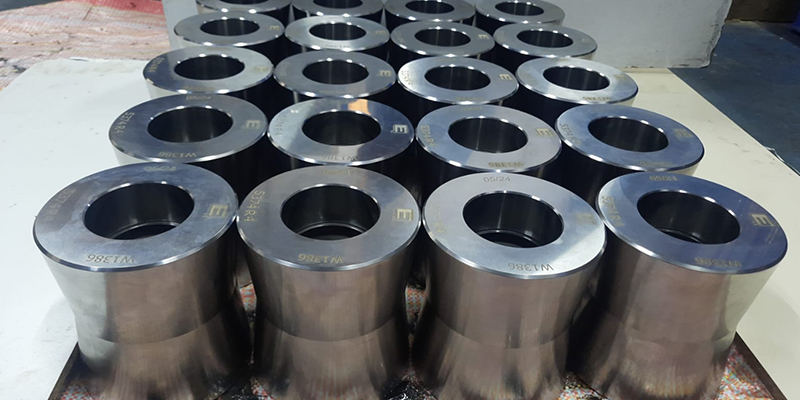

1. Rollers (Guide Rollers):

- Rollers are essential components in the rolling process. They apply pressure to the metal and reduce its thickness or alter its shape.

- Function: Rollers are essential components in the rolling process. They apply pressure to the metal and reduce its thickness or alter its shape.

- Types :

- Smooth Rollers : Provide uniform pressure.

- Grooved Rollers : Used for specific requirements.

- Position :

- Entry Guide Rollers : Positioned at the entry side of the rolling mill. They guide the stock into the roll pass and maintain alignment.

- Exit Guide Rollers : Located at the exit side of the roughing mill. They ensure smooth stock delivery.

- Material :

- High-quality alloy steel, through-hardened for maximum durability.

- Maintains high hardness throughout, minimizing wear even after repeated dressing.

- Benefits :

- Longer roller life reduces mill downtime